We are supporting the electrification of society with sustainable solutions

Our goal is to support the electrification of society with sustainable solutions. Nilar develops and manufactures batteries that are safe and re-usable. We ensure that renewable energy works in everyday life, that electricity is there when and where we need it and at the right price.

Nilar’s idea is to speed up electrification and the climate transition

We make batteries for sustainable energy storage, which is crucial for a climate transition that works, i.e. that electricity is actually there when it is needed and not just when it is generated.

Nilar develops and manufactures batteries that are safe and re-usable

It is actually the only battery in the world that can be given new life through oxygen refilling. Our batteries can be used for energy storage in homes, in commercial properties, industrial operations and for large-scale energy storage in society’s electricity infrastructure.

Management

Jørgen Krogh

CEO

Ulf Sandegren

CFO

Jan Lundquist

Head of Sales & Marketing

Anette Anderung

CSO

Joacim Wenna

CTO & Head of Product Development

Anders Mårtensson

Head of Product Management

& Services

Andreas Antonsson

Acting COO

Board of Directors

Gunnar Wieslander

Chairman of the Board

Marko Allikson

Director of the Board

Peter Wesslau

Director of the Board

John Häger

Director of the Board

Britta Dalunde

Director of the Board

Per Johansson

Director of the Board

About Nilar

Stockholm and Gävle – Swedish battery engineering at its finest.

Thanks to cutting edge expertise within battery chemistry, production technology, product development and system development, our R&D initiatives have contributed to groundbreaking innovations within Swedish battery research.

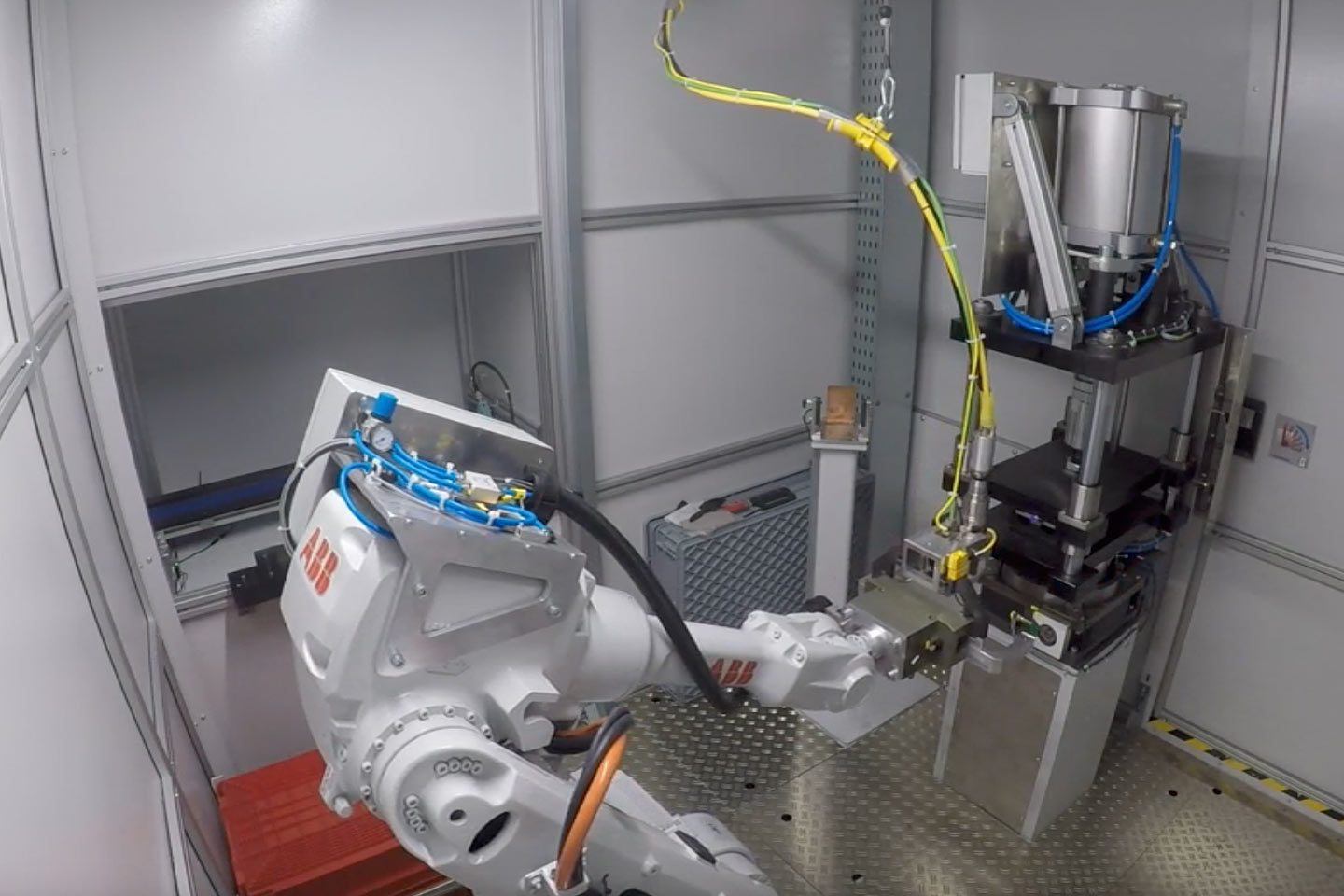

State of the art production process

As a leader in energy storage battery systems, Nilar’s focus is ensuring that every product leaving our factory meets the highest standards. Nilar puts significant investment in Research & Development as well as in our manufacturing facilities. All steps in our production process are performed at our state-of-the-art factory in Gävle, Sweden, powered by 100% renewable energy.

Production Process

These are the steps that take raw material into batteries ready for implementation into energy storage systems.

Electrode manufacturing

Automated module assembly

Laser welding

Battery pack assembly

A look inside our facility

Contact Nilar

Headquarters

Visiting and postal address:

Nilar AB

Bönavägen 55

SE-806 47 Gävle

Sweden

Phone: +46 (0)8 768 00 00

Sales, Product Management & Finance

Visiting and postal address:

Nilar AB

Stockholmsvägen 116A

SE-187 30 Täby

Sweden

Phone: +46 (0)8 768 00 00

Support

E-mail: support@nilar.com

Invoice

E-mail: invoice@nilar.com