Nilar modules

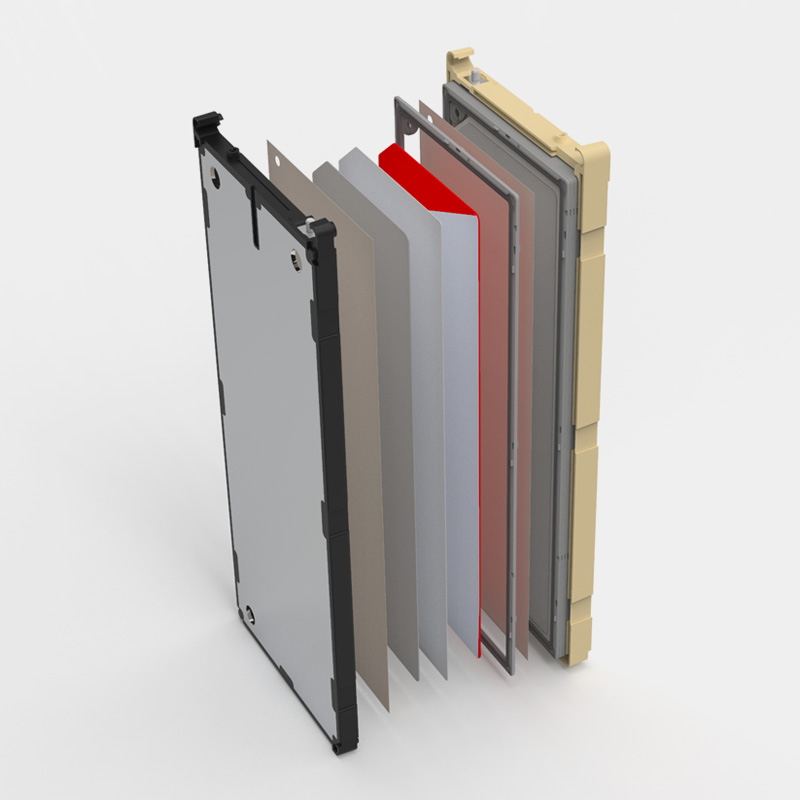

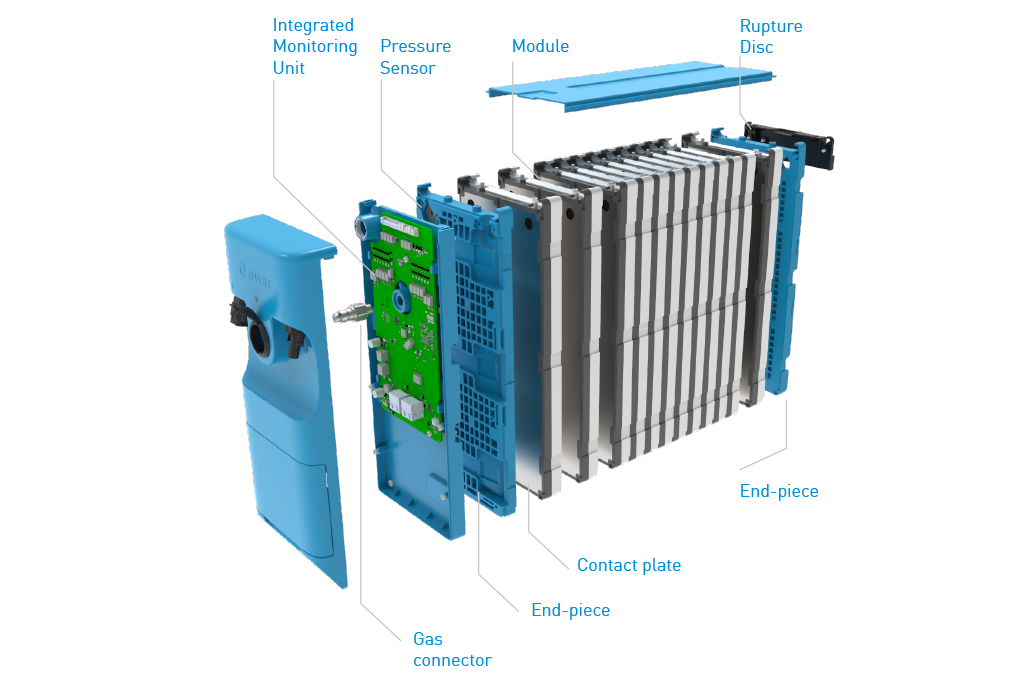

The battery modules consists of ten battery cells. Each cell contains a positive electrode, a separator, a negative electrode. The cells are stacked horizontally on top of one another with a metal bi-plate in between. This is what is called a bi-polar design. The cells are laid horizontally and stacked on top of one another to gain maximum space efficiency. The outer contact plates act as current collectors for all cells in the module, thus reducing the volumetric overhead and inherently resulting in a uniform current flow across the cell. After the module is assembled, it is filled with the electrolyte to enable free flow of ions.

Benefits of bi-polar design

- The volumetric overhead is approximately zero in comparison with other battery designs. This gives a volumetric density advantage of 10% or greater.

- Uniform current and resistance paths promote uniform heat generation, which enables uniform ageing of the cells and ensures longer cell life.

- The large current collectors make the design ideal for high discharge rate applications.

- The modular design enables easy assembly.

Electrodes

The positive and negative electrodes are manufactured by a patented method for compression of dry powders without any expensive plate support material, binders or volatile organic solvents. Active materials and additives, as dry powders, are mixed with each other before being compressed in a calender system to form continuous sheets of compressed electrode material. The sheets of active materials are cut into electrode plates. The electrode manufacturing process produces electrodes with very high accuracy on dimensions, weight and capacity, contributing to the high quality of Nilar battery packs.

Biplate

The biplates, together with the gaskets, are means for sealing each cell. The biplates also provide electrical contact between cells. In the Nilar bi-polar design, the current is perpendicular to the electrode and bi-plate surface, making the whole biplate area used for current transfer between cells. This substantially reduces resistance and optimizes uniformity of current distribution over the bi-plate and electrode surface. This bi-plate design is part of the Nilar patent portfolio.

Separator

The separator prevents electrical contact between the positive and negative electrodes in the cell while holding the electrolyte necessary for ionic transport. The superior conductivity and safety of the water-based electrolyte used in the cells allows for the separator to act as an electrolyte reservoir. The high conductivity of the electrolyte also allows for a relatively thick separator, effectively preventing short circuits from any potential defects in the separator or foreign particles.

Gasket

Each cell is surrounded by a gasket. The gasket, together with the biplates, provide a seal between the interior of the cell and the exterior. The hydrophobic properties of the gasket prevent the creation of electrolyte bridges between adjacent cells.

Electrolyte

The electrolyte in the cell provides means for ionic conductivity in the cell. The water-based electrolyte has important intrinsic features like low cost, fast filling time and excellent ionic conductivity over a wide temperature range. The electrolyte also possesses attractive safety features such as non-combustibility and energy-absorbing capability. The electrolyte is a solution of potassium hydroxide. The design is a so-called starved electrolyte design with little free volume of electrolyte in the cells. All of the electrolyte volume is absorbed by the positive and negative electrodes and the separator.

Case

The case is part of the sealing of the module together with the contact plate. The case is extruded onto the sides of the contact plate. The two case/contact plate units on each side of the 10 cell stack are connected by laser welding, forming a sealed 12 V module. Fittings in the case also make sure that all 12 V Modules are aligned when assembled into battery packs.

Contact plate

The contact plate is the positive and negative terminal on the module and is also a part of the module enclosure. The contact plate is made of aluminum. Besides transferring electrical current, the contact plate also serves as a heat conductor, moving heat from the cells to the long sides of the 12 V Module. This solution is patented by Nilar and enables efficient and low-cost air cooling of battery packs.