The Nilar ReOx® Technology

Nilar batteries are not only rechargeable, they can also be revived to full capacity at least 3 times through the Nilar patented ReOx® process. This brings savings to your wallet, but above all, makes it easy for you to do the right thing for our planet.

Extended lifetime with ReOx®

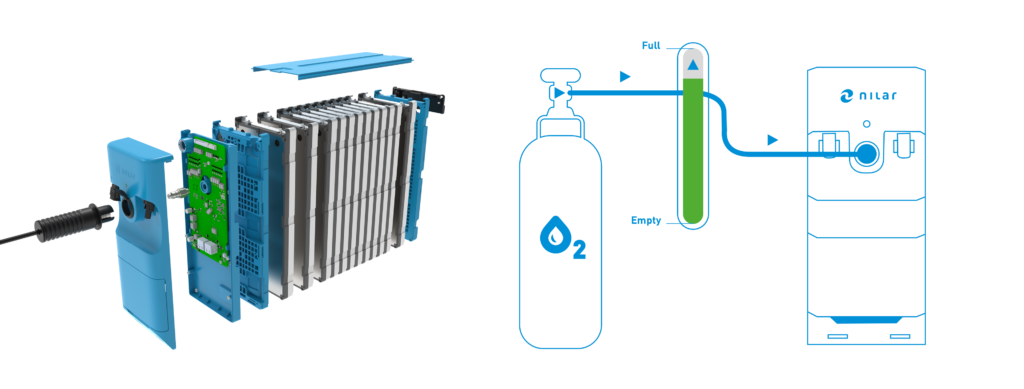

Our patented ReOx® technology balances the electrodes and replenishes the electrolyte by adding a controlled amount of oxygen. This process brings your Nilar Hydride® battery back to its initial 100% capacity, extending its useful life by more than three times.

The groundbreaking Nilar reoxygenating process

With pure oxygen, Nilar can recondition the battery and reverse its ageing process, thus regaining lost capacity. Using the reoxygenating technology, Nilar’s batteries can be used over and over again, which is both cost efficient and good for the environment.

Built on comprehensive scientific research

The reoxygenation functionality is built on thorough scientific research and extensive experimental analysis. Starting at Stockholm University, there was an exploration of the reversibility of chemical side reactions. The side reactions cause corrosion of the metal hydride component, but more importantly, consume the water within the electrolyte. This electrolyte depletion leads to the main source of failure within a Nickel Metal Hydride battery: dry out. Because Nilar Hydride® batteries utilize gas recombination reactions, a controlled introduction of gas can regenerate the water-based electrolyte.

Nilar ReOx® batteries

The sustainable choice

Sustainable by design

It is our ambition to develop and produce one of the world’s most sustainable batteries at our plant in Gävle, Sweden.